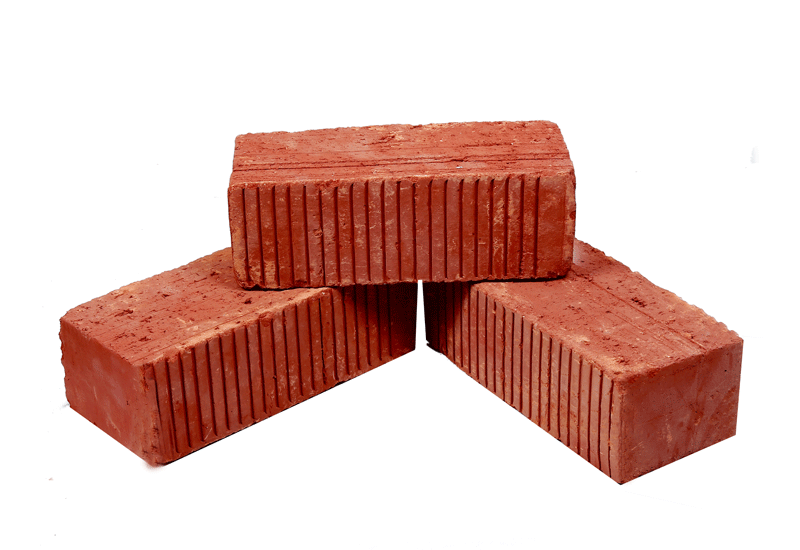

Clay Wirecut bricks are burned in a running chambers/kiln which makes them durable. The composition of clay varies over a wide range. Usually, clays are composed mainly of Silica (grains of sand), Alumina, Lime, Iron, Manganese, Sulphur, and Phosphates, in different proportions. Bricks are manufactured by grinding or crushing the clay in mills and mixing it with water to make it plastic. The plastic clay is then moulded, textured, dried, and finally fired.

Wire cut bricks are made using machineries in factory whereas table mould bricks are made by hand and hence wire cut bricks will have uniform properties, higher strength and regular surfaces compared to table mould bricks however little costlier than table mould bricks.

Our manufacturing units are well equipped with modern technology, skilled labors with high production capacity having best in class logistics to ensure quality service to customers. The Clay Wirecut bricks are manufactured with standard size and are burnt using coal in running chambers under the brand label -“MBW and BBI ”

Wirecut Bricks are easy to install, highly stable and durable. Due to their low water absorption and high compressive strength, perform exceptionally well in a variety of applications.

| Size (Length X Breadth X Thick ) | 9″ x 4″ x 3″ |

| Size (Length X Breadth X Thick ) | 9″ x 6″ x 3″ |

- Economical, Hard and durable

- Good compressive strength for normal construction

- Different orientations/sizes give different surface textures

- Low maintenance cost, Reusable and Recyclable

- Demolishing easy, less time consuming and economic

- Highly fire resistant and less environmental pollution