AAC – Autoclaved Aerated Concrete Block is a light weight and certified green building material, which can be used for the purpose of Commercial, Industrial and Residential construction.

AAC is a highly thermal insulating concrete based material used for both internal and external construction and are light in weight, energy efficient, fire proof, sound proof, easy to install and Eco friendly as it is ecological, recyclable, higher strength to weight ratio, seismic resistance, precision and breakages. These Blocks are unique and excellent building materials offers ultimate workability, flexibility and durability.

AAC was developed in 1924 by a Swedish architect, who was looking for alternate building material with properties similar to that of wood – good thermal insulation, solid structure and easy to work with without the disadvantage of combustibility, decay and termite damage. AAC has excellent thermal insulation and acoustic absorption properties. It is fire and pest resistant, economically and environmentally superior to the more traditional structural building materials such as Concrete, Wood, Brick and Stone.

AAC Blocks are as per IS 2185 (Part-3) 1984 using the finest graded Fly Ash – Grade 1 and marketing under the brand name of CONECC having multiple units across south region.

Features, Benefits & Advantages of AAC Blocks

- Eco-Friendly and Sustainable

- Lightweight

- Thermally Insulated & Energy Efficient

- Fire Resistant

- Acoustic Performance

- Easy Workability and Design Flexibility

- Seismic Resistant

- Faster Construction

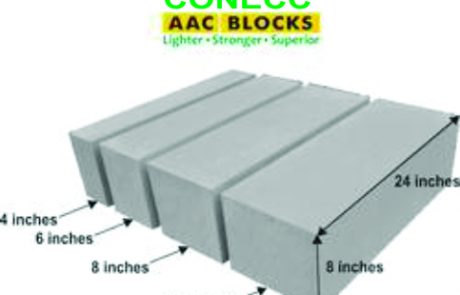

Product : Autoclave Aerated Concrete Blocks

Sizes : 600mm L x 200mm W x 75mm to 230mm W – Thickness

Precision Size : Variations 1 50 1.5mm+/-

Compressive Strength : 3.5 to 4 MPa

Fire Resistance : 1200* C/up to 7 hrs

Density : 550 – 650

Sound Reduction Index : 42-45db for 200mm thick.

Thermal Conductivity : 0.16 (k) w/m degree centigrade.

Colour : Light Grey