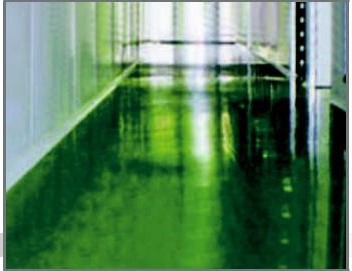

Bostik EPU SL 1000 / 2000 – 1 mm / 2 mm Epoxy – PU Self Levelling Flooring

Bostik EPU SL 1000 / 2000 is a self-leveling, EPU based pigmented topping. It has excellent flexibility and adhesive properties.

COVERAGE

Primer E2 – 5 – 6 m2 / kg.

Bostik EPU SL 1000 – 0.6m2 / kg @ 1mm thickness.

Bostik EPU SL 2000 – 0.3m2 / kg @ 2mm thickness.

Coverage may vary based on nature of substrate.

PACKAGING

Primer E2 : 1 & 5 Kg.

Bostik EPU SL 1000 – 16 Kg.

Bostik EPU SL 2000 – 17 Kg.

COLOURS AVAILABLE

Colours and shades are available based on requirement.

APPLICATION PROCEDURE

Surface Preparation

The concrete surface must be hard, sound and dry. Dust, paint should be removed from substrate prior to application of primer, New concrete floor must be allowed to cure for at least 28 days and moisture should not exceed 5%, existing concrete floor surface should be mechanically prepared by scrubbing / grinding, dust and debris should be removed using vacuum equipment, expansion or movement joint should be brought through to finished surface.

PRIMING

- All areas to be treated with Bostik EPU SL 1000 / 2000 must be primed with Primer E2.

- Add entire content of component B (hardener) into component A (base) of Primer E2.

- Mix thoroughly for 2 minutes with slow speed stirrer and apply by brush / roller on prepared surface.

- Second coat may be required depending upon the condition and porosity of the concrete substrate.

- Proper priming is required to avoid blister or pin holes in the final coating.

- Allow the Primer to tack free.

MIXING

- Bostik EPU SL 1000 / 2000 is supplied in pre weighed packs consisting of Base, Hardener, Filler & Colour concentrate.

- Base should be thoroughly stirred before adding to the hardener.

- Pour hardener into the base and mix for 2 minutes with slow speed stirrer using suitable mixing paddle. Add colour concentrate to the mixed base – hardener and mix further till achieve a uniform mix.

- Finally add filler to the homogeneous mix and stir for 2 minutes.

- One or more pack may be mixed simultaneously to ensure quick rate of application.

APPLICATION

- Mixed material should be poured on to already tack free primed surface.

- Material should spread evenly and slowly to get desired thickness by using serrated trowel.

- The surface should be gently rolled with spike roller to remove entrapped air and trowel marks.

- The applied area should be protected during application and the initial curing time.

- Type: Epoxy PU

- Colour : Any desired colour

- Pot Life: @ 27 ± 20C, in minutes 30 – 40

- Compression Strength: 60 N / mm2

- Flexural Strength: 40 N / mm2

- Tensile strength : 25 N / mm2

- Minimum hardening temp. 0C 10

- Curing time : 7 days, min.

- Surface : Dry 3 – 4 hours

- Tack free : dry 8 hours

- Hard Dry Over night

- Method of application Leveller & Spike roller

- Finish Semi-gloss

- Thinner Bostik Thinner E

Bostik EPU SL 1000 / 2000 is a flooring system for cementitious surface such as concrete, plaster, asbestos cement. The main fields of application are floors, where hygiene or high abrasion resistance is required like hospitals, pharma, food, breweries, automobiles, airport hangers, and other heavy engineering industries.

- Very hard impact and abrasion resistant.

- Weather and water proof.

- Resistant to waste and sea water.

- Suitable for organic and inorganic acids, dyes and mineral oils.

- Coated surface can be steam cleaned.

- Impermeable to carbon dioxide, thus protects concrete against carbonization.